Demineralisers

Ion exchange systems are used to purify water for laboratory, biotech, pharmaceutical, medical, food and beverage, hydro metallurgical, metals finishing, chemical and petrochemical, and nuclear, industrial water, semiconductor, power and other applications.

TBD Features

- High exchange capacity Cation & Anion PVC resin columns

- Digital conductivity meter with Regeneration alarm system

- Flexible PVC tubes with connectors for inlet & outlet water

- Housed in an attractive corrosion proof powder coated MS skid

- Compact design with castor wheels for easy mobility.

Models & Specifications

Treatment Flow | Working Pressure | Treated Water Quality | Resin quantity | |

|---|---|---|---|---|

Model | Min | Max (Liters Per Hour) | Min | Max (Kg/cm) | E.C (μS/cm) | pH | Cation | Anion |

TBD 50 | 10 | 50 | 0.5 | 2.0 | <10 | 6.5 - 10.5 | 4 | 4 |

TBD 100 | 20 | 100 | 1.0 | 2.0 | <10 | 6.5 - 10.5 | 8 | 8 |

TBD 200 | 30 | 200 | 1.5 | 2.0 | <10 | 6.5 - 10.5 | 10 | 10 |

TBD 300 | 30 | 300 | 1.5 | 2.0 | <10 | 6.5 - 10.5 | 15 | 15 |

Product Gallery

CAMB Features

- Two High exchange capacity Cation & Anion PVC resin columns

- Mixed bed PVC column charged with Cation & Anion resins together

- Digital conductivity meter with alarm system

- A set of PP diaphragm valves for easy operation & regeneration

- Housed in an attractive corrosion proof powder coated MS skid

- Electrical operated magnetic air pump for resin mixing

Models & Specifications

Treatment Flow | Working Pressure | Treated Water Quality | Resin quantity (in Liters) | |

|---|---|---|---|---|

Model | Min | Max (Lph) | Min | Max (Kg/cm) | E.C (μS/cm) | pH | Cation | Anion | MB |

CAMB 100 | 10 | 100 | 0.5 | 1.5 | <1 | 6.5 - 7.5 | 10 | 10 | 2.5 C & 4.0 A |

CAMB 200 | 20 | 200 | 1.0 | 2.0 | <1 | 6.5 - 7.5 | 12 | 12 | 3.0 C & 5.5 A |

CAMB 300 | 30 | 300 | 1.0 | 2.0 | <1 | 6.5 - 7.5 | 15 | 15 | 4.0 C & 7.0 A |

Product Gallery

CACA Features

- Two Sets of High exchange capacity Cation & Anion PVC resin columns

- Digital conductivity meter with alarm system

- A set of PP diaphragm valves for easy operation & regeneration

- Housed in an attractive corrosion proof powder coated MS skid

- Built in pre-filter to retain suspended impurities from feed

- Capable of handling water with TDS upto 1000 ppm

- Efficiently removes TDS upto 99% to produce DM water

- Economical & efficient method for removal of TDS

Mixed Bed Features

- PVC column contains both Cation & Anion resins in Mixed form

- Digital conductivity meter with alarm system

- A set of PP diaphragm valves for easy operation & regeneration

- Housed in an attractive corrosion proof powder coated MS skid

- Built in pre-filter to retain suspended impurities from feed

- Economical & efficient method for removal of TDS

- Capable of handling water with TDS upto 50 ppm,

- Efficiently removes TDS upto 99% to produce pure water

- Fully assembled and tested before despatch

Models & Specifications

Treatment Flow | Working Pressure | Treated Water Quality | Resin quantity | |

|---|---|---|---|---|

Model | Min | Max (Liters Per Hour) | Min | Max (Kg/cm) | E.C (μS/cm) | pH | Cation | Anion |

MB 100 | 10 | 100 | 0.5 | 1.5 | <1 | 6.5 - 7.5 | 2.5 | 4.5 |

MB 200 | 20 | 200 | 1.0 | 1.5 | <1 | 6.5 - 7.5 | 4.0 | 7.5 |

MB 300 | 30 | 300 | 1.0 | 2.0 | <1 | 6.5 - 7.5 | 5.0 | 9.0 |

MB 300 | 50 | 500 | 1.0 | 2.0 | <1 | 6.5 - 7.5 | 6.0 | 11.0 |

Product Gallery

RODI Features

- Efficiently removes TDS, and produces Type II Grade Ultra Pure Water

- RO Membrane Modules to reduce Feed Water TDS

- PP Micron & Carbon Cartridge Filters

- Cation, Anion & Mixed Bed Resin Cartridges

- Digital conductivity meter with alarm system

- PP Connectors for inlet & Outlet Water

- Booster Pumps, Pressure Gauges, Solenoid Valves

- Micro Processor controller for Automation with treated water storage

- Mild Steel anticorrosive Powder coated skid & accessories

- Capable of handling water of TDS levels upto 1000 ppm

Models & Specifications

Treatment Flow | Working Pressure | Treated Water Quality | Resin quantity (in Liters) | |

|---|---|---|---|---|

Model | Feed | DI (Lph) | Min | Max (Kg/cm) | E.C (μS/cm) | pH | Cation | Anion | MB |

RODI 25 | 100 | 25 | 10 | <1 | 6.5 - 7.5 | 10 | 10 | 2.5 C & 4.0 A |

RODI 50 | 200 | 50 | 10 | <1 | 6.5 - 7.5 | 12 | 12 | 3.0 C & 5.5 A |

RODI 100 | 30 | 300 | 1.0 | 2.0 | <1 | 6.5 - 7.5 | 15 | 15 | 4.0 C & 7.0 A |

Product Gallery

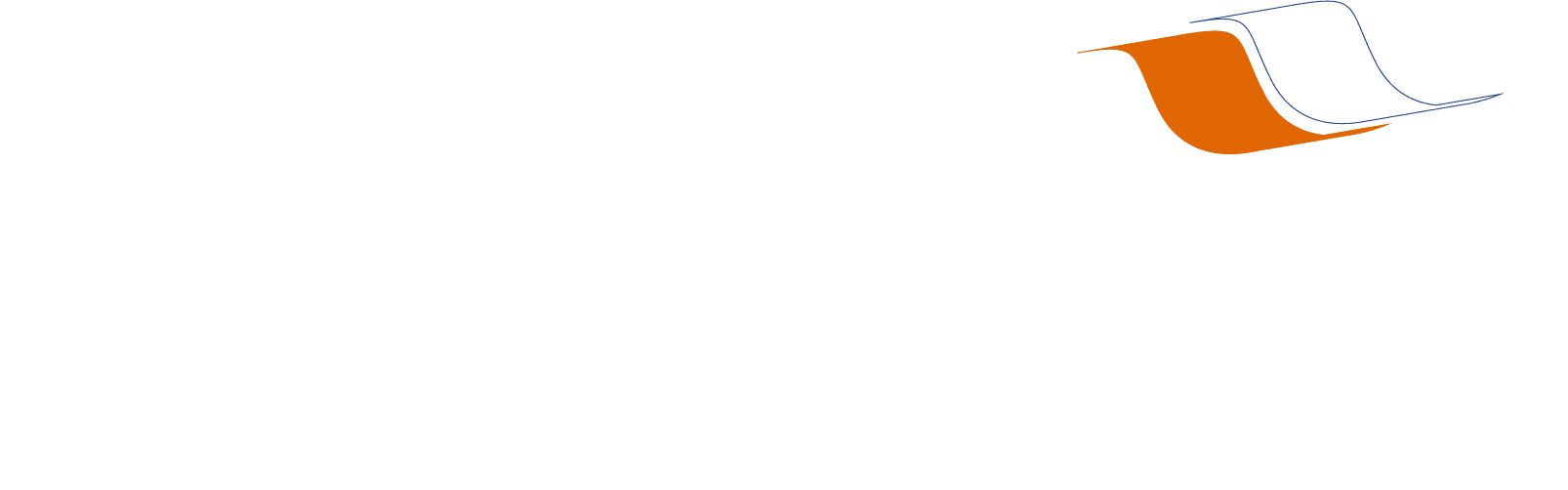

TBD Industrial Features

- Two FRP/MSFRP/MSRL vessels charged with Cation & Anion resins

- Digital conductivity meter with Regeneration alarm system

- Multiport valves/Frontal PVC pipe line with necessary valves & fittings

- Corrosion proof powder coated MS base frame mounting skid

- Corrosion proof chemical pump for regeneration

- HDPE / FRP chemical compatible tank for regeneration

- Suitable to produce <10 μS Electrical Conductivity DM water

Models & Specifications

Treatment Flow | Vessel Size | Working Pressure | Treated Water Quality | Resin Quantity | |

|---|---|---|---|---|---|

Model | Min | Max LPH | Dia | HOS | Min | Max (kgf/cm2) | E.C (μS/cm2) | pH | Cation | Anion |

TBD 500 | 100 | 500 | 8″ | 48″ | 1.5 | 2.0 | <10 μS | 6.5 ~ 9.5 | 30 | 30L |

TBD 750 | 150 | 750 | 10″ | 54″ | 1.5 | 2.5 | <10 μS | 6.5 ~ 9.5 | 50 | 50L |

TBD 1000 | 100 | 1000 | 12″ | 48″ | 1.5 | 2.5 | <10 μS | 6.5 ~9.5 | 80 | 80L |

TBD 2000 | 200 | 2000 | 14″ | 65″ | 1.5 | 2.5 | <10 μS | 6.5 ~ 9.5 | 150 | 150L |

TBD 4000 | 400 | 4000 | 31″ | 47″ | 1.5 | 3.5 | <10 μS | 6.5 ~ 9.5 | 400 | 400L |

Product Gallery

CAMB - Industrial Features

- Two FRP/MSFRP/MSRL vessels charged with Cation & Anion resins

- Mixed Bed Column charged with Cation & Anion resins in mixed form

- Suitable to produce ultra pure deionized water at E.C of <1 μS/cm2

- Digital conductivity meter with Regeneration alarm system

- Multiport valves/Frontal PVC pipe line with necessary valves & fittings

- Corrosion proof powder coated MS base frame mounting skid

- Corrosion proof chemical pump for regeneration

- HDPE / FRP chemical compatible tank for regeneration

Models & Specifications

Treatment Flow | Vessel Size | Treated Water Quality | Resin Quantity | |

|---|---|---|---|---|

Model | Min | Max LPH | Dia | HOS | E.C (μS/cm2) | pH | Cation | Anion | MB (L) |

CAMB 500 | 50 | 500 | 8″ | 48″ | <1 μS | 6.5 ~ 7.5 | 30 L | 30 L | 6C & 10A |

CAMB 750 | 150 | 750 | 10″ | 54″ | <1 μS | 6.5 ~ 7.5 | 50 | 50L |

CAMB 1000 | 100 | 1000 | 12″ | 48″ | <1 μS | 6.5 ~7.5 | 80 | 80L |

CAMB 2000 | 200 | 2000 | 14″ | 65″ | <1 μS | 6.5 ~ 7.5 | 150 | 150L |

CAMB 4000 | 400 | 4000 | 31″ | 47″ | <1 μS | 6.5 ~ 7.5 | 400 | 400L |

Product Gallery

ACAMB - Industrial Features

- FRP/MSFRP/MSRL vessel charged with Activated granular carbon

- Two FRP/MSFRP/MSRL vessels charged with Cation & Anion resins

- Mixed Bed Column charged with Cation & Anion resins in mixed form

- Produces ultra pure deionized water at E.C of <1 μS/cm2

- Removal of color, odour and free chlorine from the feed water

- Digital conductivity meter with Regeneration alarm system

- Multiport valves/Frontal PVC pipe line with necessary valves & fittings

- Corrosion proof powder coated MS base frame mounting skid

- Corrosion proof chemical pump for regeneration

- HDPE / FRP chemical compatible tank for regeneration

Models & Specifications

Treatment Flow | Vessel Size | Treated Water Quality | Resin Quantity | |

|---|---|---|---|---|

Model | Min | Max LPH | Dia | HOS | E.C (μS/cm2) | pH | Cation | Anion | MB (L) |

ACAMB 500 | 50 | 500 | 8″ | 48″ | <1 μS | 6.5 ~ 7.5 | 30 L | 30 L | 6C & 10A |

ACAMB 750 | 150 | 750 | 10″ | 54″ | <1 μS | 6.5 ~ 7.5 | 50 | 50L |

ACAMB 1000 | 100 | 1000 | 12″ | 48″ | <1 μS | 6.5 ~7.5 | 80 | 80L |

ACAMB 2000 | 200 | 2000 | 14″ | 65″ | <1 μS | 6.5 ~ 7.5 | 150 | 150L |

ACAMB 4000 | 400 | 4000 | 31″ | 47″ | <1 μS | 6.5 ~ 7.5 | 400 | 400L |

Product Gallery

Mixed Bed - Industrial Features

- Suitable to produce ultra pure deionized water at E.C of <1 μS/cm2

- FRP/MSFRP column contains both Cation & Anion resins in Mixed form

- Digital conductivity meter with alarm system

- PVC/CPVC frontal pipes line, valves for easy operation & regeneration

- Built in pre-filter to retain suspended impurities from feed water

- Corrosion proof Plastic Chemical pump for regeneration

- FRP chemical compatible tank for regeneration

- Capable of handling water with TDS upto 100 ppm

- Efficiently removes TDS upto 99% to produce pure water

RODI - Industrial Features

- Efficiently removes TDS, and produces Type II Grade Ultra Pure Water

- Produces ultra pure deionized water at E.C of <1 μS/cm2

- RO Membrane with housing to reduce Feed Water TDS

- Cation, Anion & Mixed Bed Resin columns

- Feed water Pump, Multigrade Sand & Carbon Filter, Micron Cartridges

- Dosing Pump, High Pressure Pump, Pressure Gauge

- Digital conductivity meter with alarm system

- Automatic Electronic control Panel with indicators

- Capable of handling water with TDS levels between 100 & 1500 ppm

- Can be designed at any volume based on feed water parameters

- Mild Steel anticorrosive Powder coated skid & accessories

Models & Specifications

Treatment Flow | Working Pressure | Treated Water Quality | Resin quantity (in Liters) | |

|---|---|---|---|---|

Model | Feed | DI (Lph) | Min | Max (Kg/cm) | E.C (μS/cm) | pH | Cation | Anion | MB |

RODI 200 | 650 | 200 | 10 | <1 | 6.5 - 7.5 | 10 | 10 | 2.5 C & 4.0 A |

RODM 500 | 1450 | 500 | 10 | <10 | 6.5 - 7.5 | 12 | 12 | 3.0 C & 5.5 A |

Product Gallery

ADCA - Industrial Features

- Two FRP High exchange capacity Cation & Anion resin columns

- Automated System for Regeneration of Cation & Anion resins

- Digital conductivity meter with alarm system

- Frontal CPVC Pipes & Fittings with connectors for inlet & outlet

- System is automated by micro process controller

- Chemicals are drawn directly from regeneration tanks.

- Built in pre-filter to retain suspended impurities from feed

- Chemical pump with HDPE tank for regeneration

- Continuous production of treated water

- Economical & efficient method to produce Distilled Water

Reverse Osmosis Systems

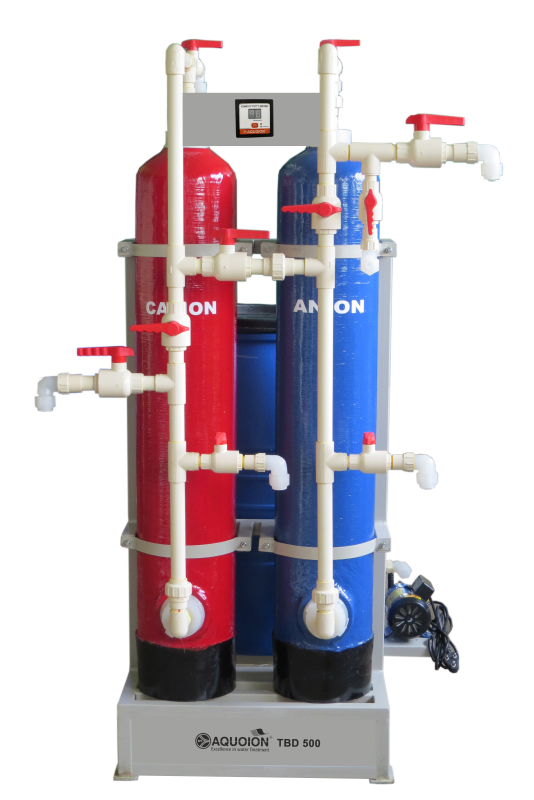

RO 250 Features

- Efficiently removes TDS or salinity upto 98% to produce pure & tasty water

- Capable of handling water at TDS levels between 500 and 2500 ppm

- Built in safety features to protect high pressure pump and RO membrane

- Includes Feed water Pump, Multigrade Sand & Carbon Filter

- Micron Housing with Cartridge Dosing Pump, High Pressure Pump

- Membrane with Housing, Low & High Pressure Switch

- SS Gly. filled Pressure Gauge Flow meter (Rotameter)

- Automatic Electronic control Panel with indicators

- CPVC Pipe line & Fittings, MS Powder coated / SS RO Skid & accessories

Technical Data

Feed Water Limiting Conditions | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

pH of Feed Water

| 6.5 to 7.0 | ||||||||||||||||||||||||||||||||||||||||||||||||

Turbidity | < 5 NTU | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Water TDS | < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Iron as Fe3 | < 0.1 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Oil & Grease | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Free Chlorine | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Temperature | 45 deg. C max. | ||||||||||||||||||||||||||||||||||||||||||||||||

Silica | < 20 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Parameters | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Feed Capacity | 900 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Quality | TDS < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Capacity | 200 – 250 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Quality | < 100 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Salt Rejection | 90 – 95% | ||||||||||||||||||||||||||||||||||||||||||||||||

System Recovery | 20 +/- 5% | ||||||||||||||||||||||||||||||||||||||||||||||||

Reject Flow Rate | 650 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Pressure | 250 psi | ||||||||||||||||||||||||||||||||||||||||||||||||

RO System can be customized based on feed water quality as per specific requirements.

Product Gallery

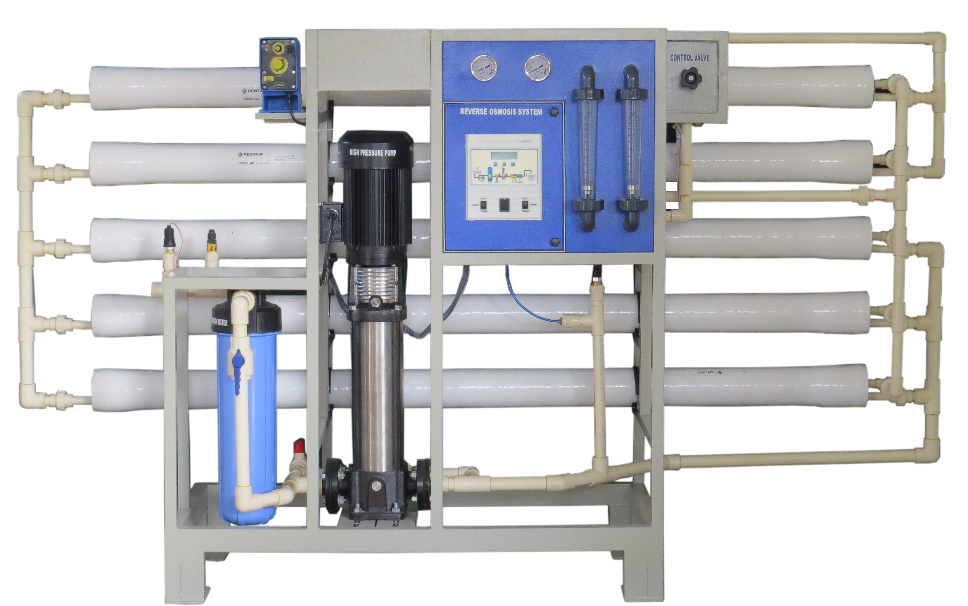

RO 500 Features

- Efficiently removes TDS or salinity upto 98% to produce pure & tasty water

- Capable of handling water at TDS levels between 500 and 2500 ppm

- Built in safety features to protect high pressure pump and RO membrane

- Includes Feed water Pump, Multigrade Sand & Carbon Filter

- Micron Housing with Cartridge Dosing Pump, High Pressure Pump

- Membrane with Housing, Low & High Pressure Switch

- SS Gly. filled Pressure Gauge Flow meter (Rotameter)

- Automatic Electronic control Panel with indicators

- CPVC Pipe line & Fittings, MS Powder coated RO Skid & accessories

Technical Data

Feed Water Minimum Requirements | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

pH of Feed Water | 6.5 to 7.0 | ||||||||||||||||||||||||||||||||||||||||||||||||

Turbidity | < 5 NTU | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Water TDS | < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Iron as Fe3 | < 0.1 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Oil & Grease | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Free Chlorine | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Temperature | 45 deg. C max. | ||||||||||||||||||||||||||||||||||||||||||||||||

Silica | < 20 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Parameters | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Feed Capacity | 1350 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Quality | TDS < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Capacity | 400 – 500 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Quality | < 100 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Salt Rejection | 90 – 95% | ||||||||||||||||||||||||||||||||||||||||||||||||

System Recovery | 30 +/- 5% | ||||||||||||||||||||||||||||||||||||||||||||||||

Reject Flow Rate | 850 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Pressure | 250 psi | ||||||||||||||||||||||||||||||||||||||||||||||||

Product Gallery

RO 750 Features

- Efficiently removes TDS or salinity upto 98% to produce pure & tasty water

- Capable of handling water at TDS levels between 500 and 2500 ppm

- Built in safety features to protect high pressure pump and RO membrane

- Includes Feed water Pump, Multigrade Sand & Carbon Filter

- Micron Housing with Cartridge Dosing Pump, High Pressure Pump

- Membrane with Housing, Low & High Pressure Switch

- SS Gly. filled Pressure Gauge Flow meter (Rotameter)

- Automatic Electronic control Panel with indicators

- CPVC Pipe line & Fittings, MS Powder coated / SS RO Skid & accessories

Technical Data

Feed Water Limiting Conditions | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

pH of Feed Water

| 6.5 to 7.0 | ||||||||||||||||||||||||||||||||||||||||||||||||

Turbidity | < 5 NTU | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Water TDS | < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Iron as Fe3 | < 0.1 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Oil & Grease | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Free Chlorine | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Temperature | 45 deg. C max. | ||||||||||||||||||||||||||||||||||||||||||||||||

Silica | < 20 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Parameters | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Feed Capacity | 1500 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Quality | TDS < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Capacity | 600 – 750 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Quality | < 60 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Salt Rejection | 90 – 95% | ||||||||||||||||||||||||||||||||||||||||||||||||

System Recovery | 50 +/- 5% | ||||||||||||||||||||||||||||||||||||||||||||||||

Reject Flow Rate | 750 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Pressure | 250 psi | ||||||||||||||||||||||||||||||||||||||||||||||||

RO System can be customized based on feed water quality as per specific requirements.

Product Gallery

RO 1000 Features

- Efficiently removes TDS or salinity upto 98% to produce pure & tasty water

- Capable of handling water at TDS levels between 500 and 2500 ppm

- Built in safety features to protect high pressure pump and RO membrane

- Includes Feed water Pump, Multigrade Sand & Carbon Filter

- Micron Housing with Cartridge Dosing Pump, High Pressure Pump

- Membrane with Housing, Low & High Pressure Switch

- SS Gly. filled Pressure Gauge Flow meter (Rotameter)

- Automatic Electronic control Panel with indicators

- CPVC Pipe line & Fittings, MS Powder coated / SS RO Skid & accessories

Technical Data

Feed Water Limiting Conditions | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

pH of Feed Water

| 6.5 to 7.0 | ||||||||||||||||||||||||||||||||||||||||||||||||

Turbidity | < 5 NTU | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Water TDS | < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Iron as Fe3 | < 0.1 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Oil & Grease | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Free Chlorine | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Temperature | 45 deg. C max. | ||||||||||||||||||||||||||||||||||||||||||||||||

Silica | < 20 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Parameters | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Feed Capacity | 1800 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Quality | TDS < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Capacity | 1000 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Quality | < 100 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Salt Rejection | 90 – 95% | ||||||||||||||||||||||||||||||||||||||||||||||||

System Recovery | 50 +/- 5% | ||||||||||||||||||||||||||||||||||||||||||||||||

Reject Flow Rate | 800 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Pressure | 250 psi | ||||||||||||||||||||||||||||||||||||||||||||||||

RO System can be customized based on feed water quality as per specific requirements.

Product Gallery

RO 2000 Features

- Efficiently removes TDS or salinity upto 98% to produce pure & tasty water

- Capable of handling water at TDS levels between 500 and 2500 ppm

- Built in safety features to protect high pressure pump and RO membrane

- Includes Feed water Pump, Multigrade Sand & Carbon Filter

- Micron Housing with Cartridge Dosing Pump, High Pressure Pump

- Membrane with Housing, Low & High Pressure Switch

- SS Gly. filled Pressure Gauge Flow meter (Rotameter)

- Automatic Electronic control Panel with indicators

- CPVC Pipe line & Fittings, MS Powder coated / SS RO Skid & accessories

Technical Data

Feed Water Limiting Conditions | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

pH of Feed Water

| 6.5 to 7.0 | ||||||||||||||||||||||||||||||||||||||||||||||||

Turbidity | < 5 NTU | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Water TDS | < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Iron as Fe3 | < 0.1 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Oil & Grease | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Free Chlorine | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Temperature | 45 deg. C max. | ||||||||||||||||||||||||||||||||||||||||||||||||

Silica | < 20 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Parameters | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Feed Capacity | 3000 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Quality | TDS < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Capacity | 2000 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Quality | < 60 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Salt Rejection | 90 – 95% | ||||||||||||||||||||||||||||||||||||||||||||||||

System Recovery | 70 +/- 5% | ||||||||||||||||||||||||||||||||||||||||||||||||

Reject Flow Rate | 1000 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Pressure | 250 psi | ||||||||||||||||||||||||||||||||||||||||||||||||

RO System can be customized based on feed water quality as per specific requirements.

Product Gallery

RO 5000 Features

- Efficiently removes TDS or salinity upto 98% to produce pure & tasty water

- Capable of handling water at TDS levels between 500 and 2500 ppm

- Built in safety features to protect high pressure pump and RO membrane

- Includes Feed water Pump, Multigrade Sand & Carbon Filter

- Micron Housing with Cartridge Dosing Pump, High Pressure Pump

- Membrane with Housing, Low & High Pressure Switch

- SS Gly. filled Pressure Gauge Flow meter (Rotameter)

- Automatic Electronic control Panel with indicators

- CPVC Pipe line & Fittings, MS Powder coated / SS RO Skid & accessories

Technical Data

Feed Water Limiting Conditions | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

pH of Feed Water

| 6.5 to 7.0 | ||||||||||||||||||||||||||||||||||||||||||||||||

Turbidity | < 5 NTU | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Water TDS | < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Iron as Fe3 | < 0.1 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Oil & Grease | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Free Chlorine | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Temperature | 45 deg. C max. | ||||||||||||||||||||||||||||||||||||||||||||||||

Silica | < 20 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Parameters | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Feed Capacity | 6750 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Quality | TDS < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Capacity | 5000 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Quality | < 60 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Salt Rejection | 90 – 95% | ||||||||||||||||||||||||||||||||||||||||||||||||

System Recovery | 75+/- 5% | ||||||||||||||||||||||||||||||||||||||||||||||||

Reject Flow Rate | 1750 litres/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Pressure | 250 psi | ||||||||||||||||||||||||||||||||||||||||||||||||

RO System can be customized based on feed water quality as per specific requirements.

Product Gallery

RO 15000 (15m 3) Features

- Efficiently removes TDS or salinity upto 98% to produce pure & tasty water

- Capable of handling water at TDS levels between 500 and 2500 ppm

- Built in safety features to protect high pressure pump and RO membrane

- Includes Feed water Pump, Multigrade Sand & Carbon Filter

- Micron Housing with Cartridge Dosing Pump, High Pressure Pump

- Membrane with Housing, Low & High Pressure Switch

- SS Gly. filled Pressure Gauge Flow meter (Rotameter)

- Automatic Electronic control Panel with indicators

- CPVC Pipe line & Fittings, MS Powder coated / SS RO Skid & accessories

Technical Data

Feed Water Limiting Conditions | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

pH of Feed Water

| 6.5 to 7.0 | ||||||||||||||||||||||||||||||||||||||||||||||||

Turbidity | < 5 NTU | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Water TDS | < 2000 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Iron as Fe3 | < 0.1 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Oil & Grease | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Free Chlorine | Nil | ||||||||||||||||||||||||||||||||||||||||||||||||

Temperature | 45 deg. C max. | ||||||||||||||||||||||||||||||||||||||||||||||||

Silica | < 20 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Parameters | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Feed Capacity | 19.5 m3/hr @ 3 bar | ||||||||||||||||||||||||||||||||||||||||||||||||

Feed Quality | TDS < 1660 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Capacity | 15 m3/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Output Quality | < 50 ppm | ||||||||||||||||||||||||||||||||||||||||||||||||

Salt Rejection | 90 – 95% | ||||||||||||||||||||||||||||||||||||||||||||||||

System Recovery | 75+/- 2% | ||||||||||||||||||||||||||||||||||||||||||||||||

Reject Flow Rate | 4.5 m3/hr | ||||||||||||||||||||||||||||||||||||||||||||||||

Operating Pressure | 300 psi | ||||||||||||||||||||||||||||||||||||||||||||||||

RO System can be customized based on feed water quality as per specific requirements.

Product Gallery

Mixed Bed - Industrial Features

- Suitable to produce ultra pure deionized water at E.C of <1 μS/cm2

- FRP/MSFRP column contains both Cation & Anion resins in Mixed form

- Digital conductivity meter with alarm system

- PVC/CPVC frontal pipes line, valves for easy operation & regeneration

- Built in pre-filter to retain suspended impurities from feed water

- Corrosion proof Plastic Chemical pump for regeneration

- FRP chemical compatible tank for regeneration

- Capable of handling water with TDS upto 100 ppm

- Efficiently removes TDS upto 99% to produce pure water

Water Softeners

Water softener consists of high exchange capacity strongly acidic cation – sodium form resin. The cation resin is used to exchange sodium ions with scale forming calcium and magnesium, and thus produce soft water, the ion exchanger is regenerated with a Brine (Nacl – sodium chloride) solution when the bed is exhausted

Features

- MS-FRP lined pressure vessel to protect from corrosion

- Built in safety features to protect high pressure to safe guard the feed pump

- Capable of handling water TH upto 1000 ppm

- Efficiently removes Total Hardness from the feed water & produce soft water

- Multiport valves/Frontal PVC pipe line with necessary valves & fittings

- Fully assembled and tested before despatch

Models & Specifications

Treatment Flow | Vessel Size | Working Pressure | Treated Water Quality | Resin Quantity | |

|---|---|---|---|---|---|

Model | Liters/Hour | Dia | HOS (mm) | Min | Max (kgf/cm2) | Total Hardness (ppm) | Liters |

SOFT 1000 | 1000 | 325 X 1350 | 2.0 | 3.5 | <30 ppm | 100 L |

SOFT 5000 | 5000 | 750 X 1200 | 2.0 | 3.5 | <30 ppm | 500 L |

SOFT 10m3 | 10000 | 1100 X 1200 | 2.0 | 3.5 | <30 ppm | 1000 L |

SOFT 20m3 | 20000 | 1250 X 1800 | 2.0 | 3.5 | <30 ppm | 2000 L |

Product Gallery

Multi Grade Filtration Systems: MGF/PSF

The raw water is filtered through a filter media which contains multi-grade sand & pebbles (MGF) in order to remove the suspended matter, turbidity, and colloidal matter present in the feed water. The MGF is made-up of Mild Steel vessel inside coated with anti-corrosive FRP lining. Internally, it is fitted with inlet distributor and bottom collecting system. Externally it is equipped with MS frontal pipe work with necessary valves & fittings.

This unit is charged with different grades of filtering pebbles and sand. Suspended matter gets entrapped when raw water is passed in downward direction through layers of different grades of sand bed. The MGF is isolated for backwash when the pressure drop across the filtering bed is more than specified limit.

Activated Carbon Filter: ACF

Activated Carbons are the most powerful adsorbent known. It is basically a solid material consisting mainly of pure carbon. A characteristic feature is its porous structure and the 2 resulting immense surface area which may be as large as 1500 m /gm. due to its exceptional adsorption qualities.

Activated carbon is widely used in process destined to purify, discolor, recuperate and remove odors at low cost and superior efficiency. Activated carbons work on the principle of adsorption. Adsorption is an interfacial process involving the collection of gaseous or solute components on the surface of adsorbent solids. This phenomenon is associated with physical attractive forces that bind gaseous and solute molecules commonly known as Van-der-Waals forces. Adsorption is thus a physical process, i.e. the substances adsorbed on the solid do not undergo any chemical reaction with the latter. The adsorbing solid is referred to as adsorbent and the substance to be adsorbed from the liquid or the gas phase as the solute. The adsorption power and rate is determined by the kind of activated carbon, the particle size, the pore size and its distribution.

MGF & Activated Carbon Filters can be designed & supplied based on the buyer’s requirements.